A chamfer cutter, or a chamfer mill, is found at any machine shop, assembly floor, or hobbyist’s garage. These cutters are quite obvious tools that are useful for chamfering or beveling any kind within a wide array of materials. Many reasons exist to chamfer an element, which range from fluid flow and safety, to part aesthetics.

As a result of diversity of needs, tooling manufacturers offer a variety of angles and sizes of chamfer cutters, as well as various kinds of chamfer cutter tip geometries. Harvey Tool, for instance, offers 21 different angles per side, including 15° to 80°, flute counts of two in order to six, and shank diameters starting at 1/8” as much as 1 inch.

After locating a tool using the exact angle they’re trying to find, an individual may have to choose a certain chamfer cutter tip that will work best with their operation. Common types of chamfer cutter tips include pointed, flat end, and end cutting. These three forms of chamfer cutter tip styles, offered by Harvey Tool, each serve an exceptional purpose.

Three Types of Harvey Tool Chamfer Cutters

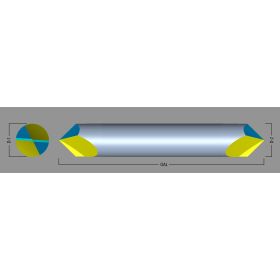

Type I: Pointed

This kind of chamfer cutter could be the only Harvey Tool option which comes into a sharp point. The pointed tip allows the cutter to perform in smaller grooves, slots, and holes, in accordance with the opposite two types. This style also allows for easier programming and touch-offs, since point can be located. It’s because tip this type of the cutter has got the longest duration of cut (together with the tool coming to a finished point), in comparison to the flat end of the other types of chamfer cutters. With simply a 2 flute option, here is the easiest sort of a chamfer cutter available from Harvey Tool.

Type II: Flat End, Non-End Cutting

Type II chamfer cutters are extremely just like the type I style, but feature a finish that’s ground down to a set, non-cutting tip. This flat “tip” removes the pointed area of the chamfer, the actual weakest section of the tool. Because of this change in tool geometry, this tool is offered a different measurement for a way a lot longer the tool would be if it stumbled on a point. This measurement is called “distance to theoretical sharp corner,” which assists with the programming with the tool. The main benefit of the flat end of the cutter now enables multiple flutes to exist around the tapered profile with the chamfer cutter. With an increase of flutes, this chamfer has improved tool life and handle. The flat, non-end cutting tip flat does limit its utilization in narrow slots, but an additional is a lower profile angle with better angular velocity with the tip.

Type III: Flat End, End Cutting

Type III chamfer cutters are a greater plus much more advanced version of the sort II style. The type III features a flat end tip with 2 flutes meeting at the center, developing a center cutting-capable version of the sort II cutter. The middle cutting geometry of the cutter assists you to cut featuring its flat tip. This cutting permits the chamfer cutter to lightly reduce the top of the an important part towards the bottom of computer, rather than leave material behind when cutting a chamfer. There are lots of situations where blending of your tapered wall and floor is required, and that is where these chamfer cutters shine. The top diameter is additionally held with a tight tolerance, which significantly supports programing it.

To conclude, there may be many suitable cutters for the single job, and you will find many questions you have to ask before picking your ideal tool. Selecting the most appropriate angle is dependant on ensuring the angle for the chamfer cutter matches the angle about the part. One needs to be aware of the way the angles are classified as out, also. Is the angle an “included angle” or “angle per side?” Will be the angle called off of the vertical or horizontal? Next, the larger the shank diameter, the stronger the chamfer along with the longer the size of cut, but now, interference with walls or fixtures have to be considered. Flute count depends upon material and finish. Softer materials have a tendency to want less flutes for much better chip evacuation, while more flutes will be finish. After addressing each of these considerations, the right style of chamfer on your job should be abundantly clear.

Check out about chamfer cutter check out this popular web site