There are several titles through which the centrifugal pumps are recognized including the hydrodynamic pump as well as the dynamic tension pump motor. As the name suggests, the pump is manufactured using the basics of centrifugal force in consideration. The kinetic energy made due to rotation in the turbine or electric engine/motor unit is turned to tension inside the liquid and therefore the stream comes about.

Features Of Centrifugal Pumps

When you compare these pumps together with other pumps, they may be much easier-to-install. These are constructed by way of the entire process of back again pullout-style. During times of restoration, the parts could be considered away from each other, set and job restarted in a simple duration. But, you require the assistance of an experienced for the greatest.

Device

The obligation of relocating any substance is performed through the impellers. The most important aspect is naturally, the technical close off that helps prevent the fluids from leaking externally through the insides in the centrifugal pump.

The key system of the centrifugal push is made up of impeller, water pump axis, bearing, stuffing pack, close diamond ring and water pump system.

Considering that the process involves activity of essential fluids, a lot of stress should be dealt inside of the pump motor. The leakage of fluids can happen if the components are not properly attached. The technical seals provide between your pumping shaft and house aid in maintaining a tab on the stress brought on as a result of rotation of shafts. However, the seals vary in size and functions as they are designed as per the industry and their work function.

Businesses

Various kinds of sectors use centrifugal pumps and they also fluctuate from ecological vegetation, fabric market sectors, power stations, food sectors and water desalination plants.

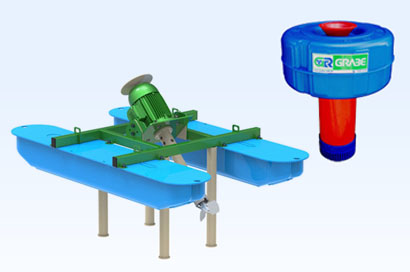

Centrifugal pumps can even be created the very best utilization of in huge backyards or water ponds.

Selection Of Low quality Quality Closes

If the leakage happens, just imagine the catastrophe that can be caused. There may be loss of resources and life.

Failures

If you have got an inexperienced operator, naturally the electric motor will be affected as the impeller will get affected. In this instance, a quick motion is vital.

If the centrifugal pumps displays signals of vibration and gives noise, then the impeller has become eroded. A few of the debris may have came into the impeller as well as the outcome is rust. The impeller has to be changed for correct working of your centrifugal pump motor.

If there is low pressure in the pump or low level of chemical fluids, then it is necessary that the pump be heated so that the flow is smooth.

If the shaft, impeller are not properly aligned, there can be un-balancement. The water pump might shake vigorously along with the outcome is going to be other areas can get loosened, as well as the complete parts are affected harm.

To read more about grabe.ind.br you can check our website.